Almight

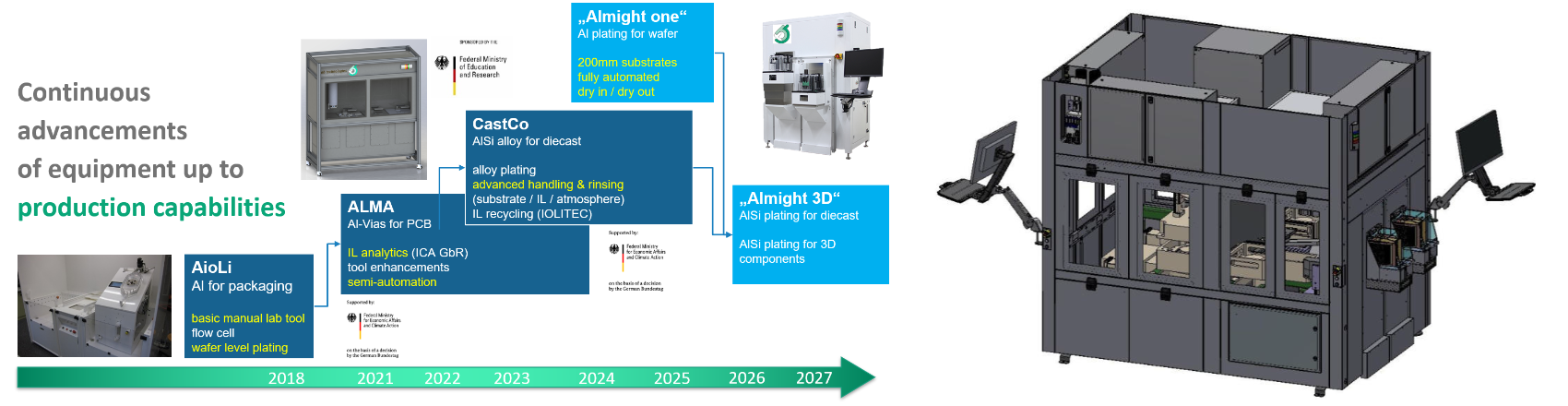

NB Technologies considers itself a pioneer in the commercial use of aluminum electroplating from ionic liquids for the semiconductor industry and other applications. We present ourselves as a system provider covering all aspects of this technology.

This includes:

- The “NB IoLiPlate® Al” electrolyte family with various additive systems (based on EMIM Cl:AlCl3)

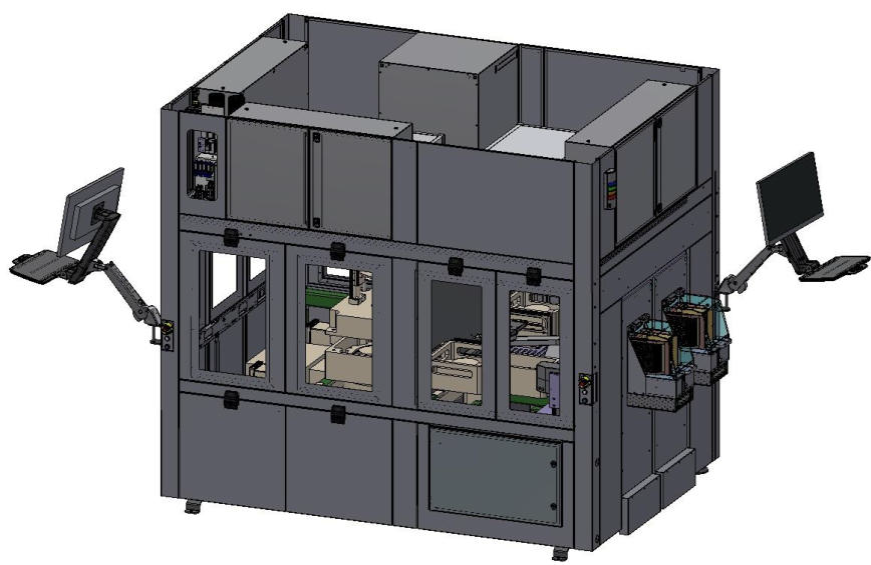

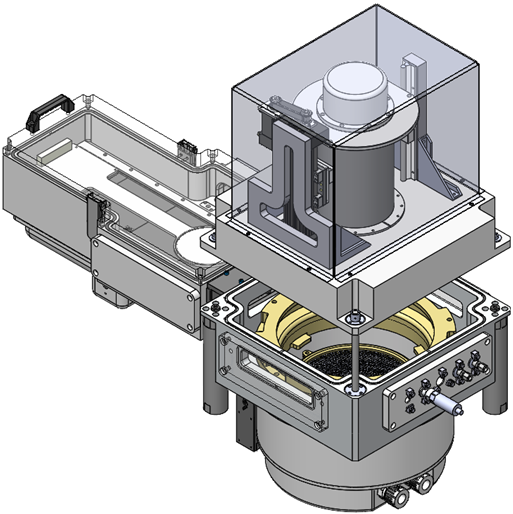

- Almight® equipment technology providing full automation for “dry in – dry out” operation (currently up to 200 mm wafer format, later also 300 mm)

- Process expertise and process implementation for customer-specific applications

- Established methods for analyzing process baths for all components

- User-friendly methods and services for bath maintenance

NB Technologies has been engaged in aluminum electroplating from ionic liquids for about ten years. During this time, several developments concerning processes and laboratory equipment have been pursued. The biggest obstacles to commercializing and establishing this technology in the semiconductor sector lie in the specific requirements for process control. The process must be carried out under a dry, inert atmosphere, as the electrolyte otherwise decomposes upon contact with moisture and releases aggressive gases (HCl).

The “chicken-and-egg” problem

As a consequence, there have been no established commercial electrolytes or equipment technologies available on the market. Without electrolytes or a proven process and equipment, the industry will not consider adopting such technology. Conversely, without industrial applications and demand, no process or equipment will be developed.

NB Technologies, through close cooperation with various industry and research partners including Fraunhofer ENAS, will now overcome this problem by offering a complete commercial process solution covering all aspects.

Entry into the technology

Demonstration processes on the Almight® One — our first fully automated system installed at Fraunhofer ENAS — will be available starting in 2026. Inquiries are welcome.

In addition to automated processes, in 2026 we will also offer a user-friendly laboratory system for research and development that goes beyond simple beaker plating, helping customers and users begin developing their own applications. The laboratory system is a streamlined version of the automated Almight® unit, ensuring that transferring developments to a production-scale system can be accomplished with minimal effort. The lab version is semi-automated and designed for compact laboratory setups, with separated grey and white room areas, and dimensions significantly reduced to approximately 60 cm × 180 cm.